Critical Barrier Properties for Dry Fruits Shelf Stability

Moisture and Oxygen Barrier Requirements to Prevent Rancidity and Clumping

To keep dry fruits fresh, they need really good moisture protection, something around 0.1 grams per square meter per day water vapor transmission rate at least. Otherwise we get clumping and all sorts of bad microbes growing on them. At the same time, oxygen levels should stay under about half a cubic centimeter per square meter daily because when oxygen gets in, it starts breaking down those fats in nuts and seeds, which makes everything go rancid fast. The best stand up pouches out there actually layer metallized films with some aluminum foil inside to create this double protection system. According to recent studies from Food Stability Research back in 2024, this kind of packaging can make products last about 30% longer than regular packaging options. And let's face it, if walnuts aren't getting those two protections right, they'll start losing their crunch pretty quickly, usually within just two weeks on shelves.

Light, Odor, and Contaminant Protection for Premium Product Integrity

Sunlight causes chemical reactions that fade apricots and break down their vitamins, while outside smells can ruin the subtle taste profiles. The solution comes in high barrier stand up pouches designed specifically for these issues. These pouches feature dark or dull exteriors that stop about 99.7 percent of harmful UV rays from getting through. Inside, special lining contains minerals that grab onto unwanted odors and eliminate them. The seams are also built tough enough to withstand at least five pounds per square inch pressure, keeping out dirt and insects. All these protective layers work together to keep foods tasting fresh longer. For instance, studies found that cranberries stored in light blocking pouches kept nearly 89% more vitamin C content after sitting around for half a year according to research published in Food Chemistry Journal back in 2023.

Food-Grade Material Compliance and Shelf-Stable Certification Standards

Packaging materials need to meet strict FDA standards along with EC Regulation 1935/2004 which bans things like phthalates and bisphenol from migrating into food products. For shelf stable items, companies should look for materials certified under ISO 22000 for proper food safety management. These materials go through rigorous testing to ensure they don't transfer more than 10 parts per million of substances overall. Third party validation is also essential here, with many manufacturers relying on studies from organizations like SGS to prove their packaging remains stable for at least twelve months when stored properly in actual warehouse conditions. Using non compliant materials can lead to faster spoilage rates and serious financial consequences too. Under FSMA regulations, violations could cost businesses as much as fifty thousand dollars each time they happen. That's why it's so important for manufacturers to check all the paperwork thoroughly before buying any new packaging supplies.

Resealable Stand Up Pouch Benefits for Consumer Experience and Freshness

Zipper Functionality for Portion Control, Convenience, and Repeat Usage

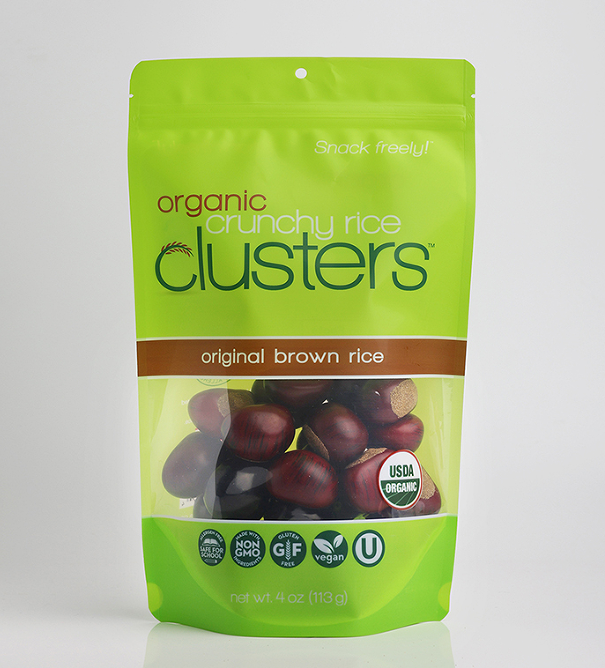

Zipper closures built right into snack packaging let people control how much they eat at once, which helps them snack smarter without losing out on convenience. The whole thing opens with one hand so folks can grab what they need quickly when running around all day, plus it seals again properly to keep moisture and dirt away from their snacks. Some tests done by packaging experts found these zippers cut down on spills by almost three quarters versus regular bag designs. When snacks stay sealed tight between meals, they tend to keep their crunchiness longer and don't lose that fresh taste or smell after being opened several times throughout the week.

Measured Shelf Life Extension: How Resealability Reduces Waste and Enhances Value

Good resealing works against things like stale chips and clumpy powders because it keeps air from getting in after opening and stops moisture from moving around inside the package. Studies show that these stand up pouches with reseal features actually keep products fresh on shelves about 25 to 40 percent longer than regular single use bags, which means less food ends up thrown away at home. The latest Sustainable Packaging Report from 2023 found families can save roughly $186 every year just by keeping their snacks and other items fresher for longer periods. People tend to stick with brands that offer this kind of feature since they link resealable packaging to better quality preservation and also see it as a smart choice for reducing waste when shopping for groceries.

Stand Up Pouch Sizing, Shape, and Design Optimization for Dry Fruits

Matching Pouch Volume and Dimensions to Common Dry Fruit SKUs (Nuts, Seeds, Apricots, etc.)

Getting the right stand up pouch size and shape makes all the difference when it comes to keeping dry fruits safe, making them look good on store shelves, and cutting down on wasted space. Small dense stuff like almonds or pumpkin seeds work best in those compact flat bottom pouches around 100-200 grams. These stop things from moving around inside and getting crushed during transport. When dealing with bigger, odd shaped items such as dried apricots or figs though, taller gusseted designs are much better because they can handle the extra volume without squishing everything together. Bad packaging choices actually cause problems down the line too. Studies show that mismatched packaging leads to about 18% more damaged goods and pushes shipping costs up roughly 12% because boxes don't stack properly on pallets according to Packaging Engineering Review findings from last year. There are plenty of other factors worth thinking about when choosing packaging solutions for different types of dried fruit products.

- Volume-to-weight ratios: Almonds require ~30% less pouch height than lighter banana chips at equal weights.

- Shape stability: Flat-bottom pouches prevent toppling–critical for fragile items like freeze-dried berries.

-

Fill efficiency: Overly large pouches accelerate oxidation; undersized ones crush contents.

Precise dimension alignment reduces material usage by 22% while ensuring premium product presentation.

Preserving Organoleptic Quality: Flavor, Texture, and Aroma in Stand Up Pouches

Keeping those delicious characteristics of dry fruits intact flavor, crunchiness, and that wonderful smell needs some pretty smart packaging solutions in stand up pouches. When oxygen gets in, those tasty flavors start fading away after about a month. And if there's more than 3% humidity around, nuts and seeds just get all stuck together (as noted in the latest food packaging research from 2024). The best packages use multiple layers with special coatings either shiny metal ones or clear barriers that stop almost all oxygen and moisture from getting inside. Those handy resealable zippers make a big difference too, because they keep air out when people open the bag again and again. For things like dried apricots that really care about smells, some packages have extra layers that actually soak up bad odors called ethylene gases which make stuff go stale faster. People notice these differences too. Most snack shoppers say they'll buy again mainly because the taste stays consistent. Good packaging stops fats from going rancid and keeps moisture where it belongs, so almonds stay crunchy and Turkish figs keep that sweet honey flavor everyone loves. This matters a lot for brands wanting to stay popular over time.